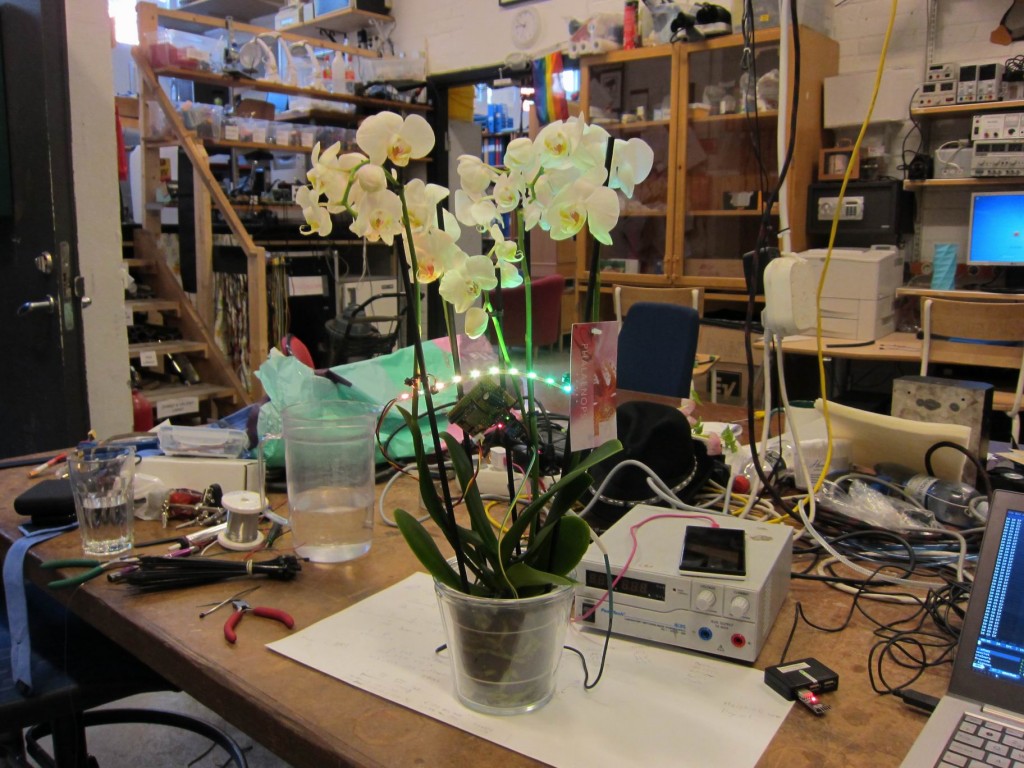

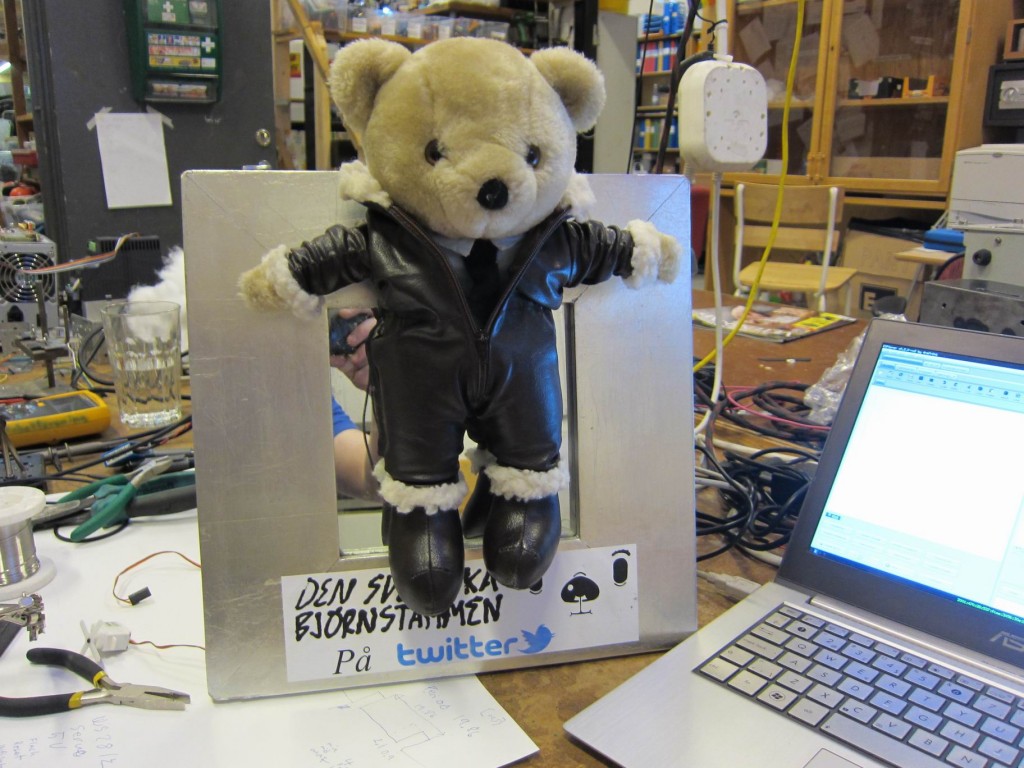

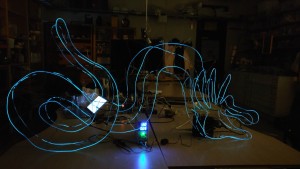

For the larp Do Androids Dream we needed a lot of small props to give a Blade Runner feeling of the scene.

An iconic part of the movie is the dragon sign above the Noodle Bar. I thought i could be made out of el wire and it could, it even looked like neon. The light emitting from the el wire was really low doh, I would prefer to have stronger light.

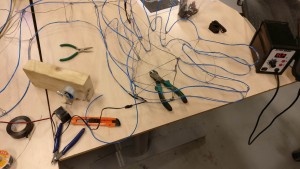

I started out by placing steel wire in the dragons shape by hand.

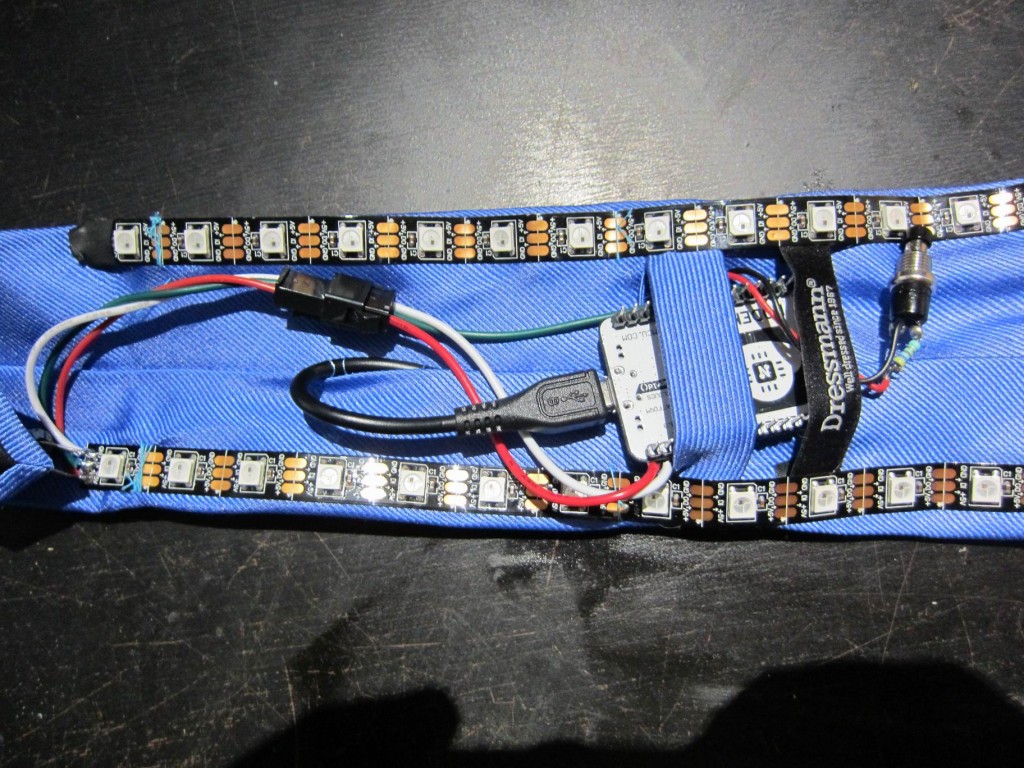

Attaching el wire around the steel wire frame was quite easy, just a matter of placing some transparent tape around it.

When trying out the outer shape I know I was on the right track, it looked great!

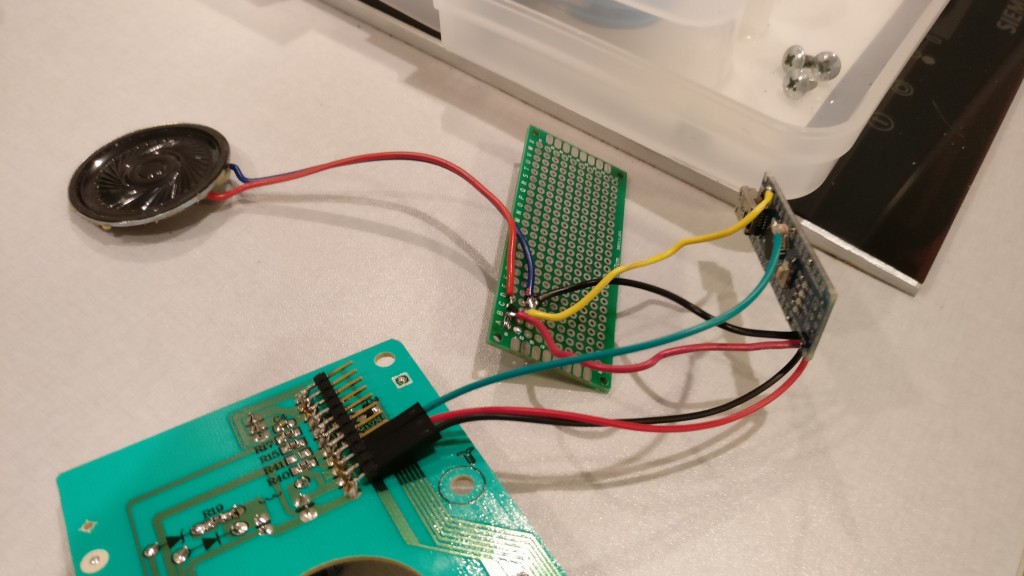

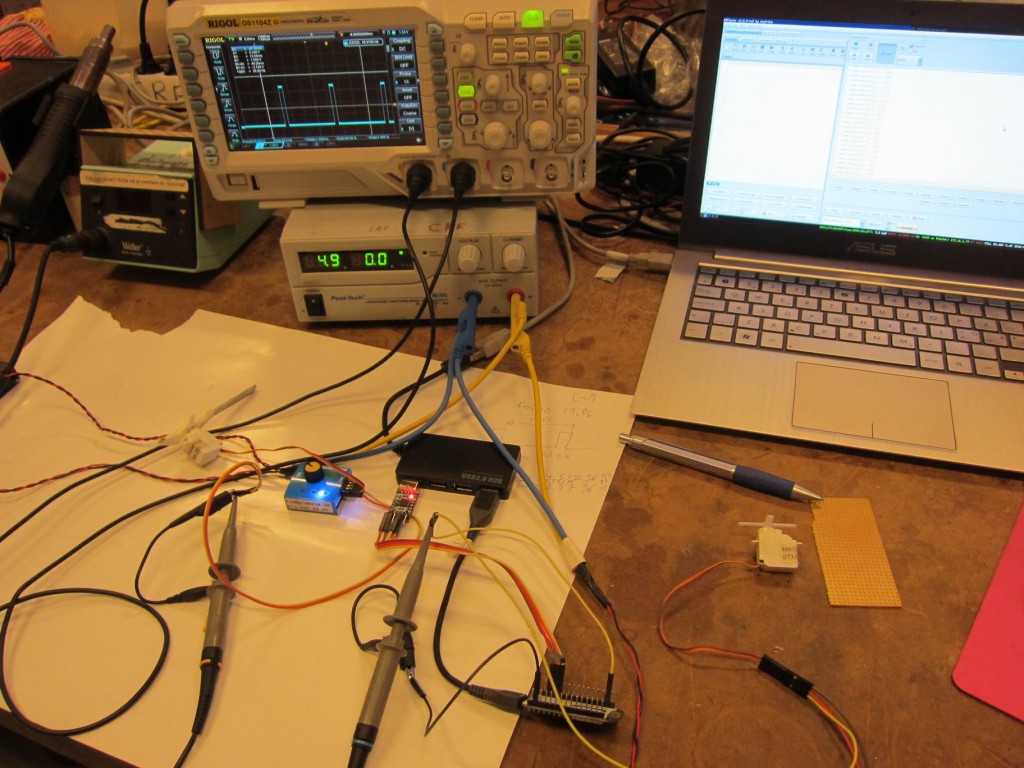

The dragons tongue is animated in the movie, it’s animated in segments. I was after the same look, so I created two segments for the tongue and had the idea the enabling each segment by turning on and off the high voltage el wire transformers.

I connected a couple of N-channel MOSFET IRLML6344 and connected it to a Arduino Nano.