Here we have placed our hotbending machine on the joint that is to be bent.

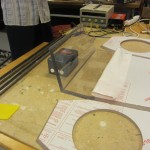

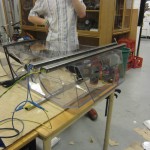

We used aluminum-foil and paper to isolate material that we didn’t wanted bent.

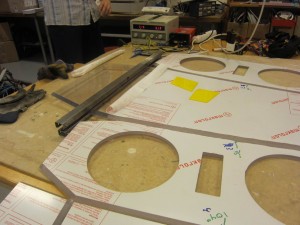

Vilse removed some plastic left from the CNC.

We used our laser-cutted acrylic angeles to bend the polycarbonate-sheet in to the right angle.

We placed this böp to let the joint cool down

15 seconds left of our 4:25 timer, the heating of the polycarbonate is almost ready.

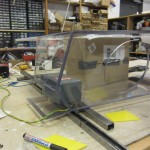

We used straps to hold the last bend

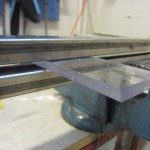

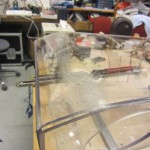

The last bend is a round corner, the radius is 200mm. We knew it would be very hard to bend it.

We heated like 100mm of the polycarbonate with both hot air gun and the heat bending machine. We heated the area for at least 20 minutes, it wouldn’t bend.

At last the polycarbonate was bending, but it turned out ugly as hell. A lot of bubbles and ugly artifacts, at least this side won’t be that visible.

Our heating machine turned out to be far more superior to the hot air gun.

Lesson learned, never make round curves in polycarbonate!

This is what the backpack will look like. The 12kg weight of the polycarbonate didn’t feel heavy at all. I think the weight will be ok.

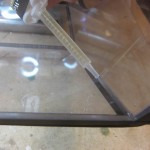

To hold the corners of our speakerbox, we use a two-component poly-urethane glue (3M Scotch-Weld Urethane Adhesive DP-610). We got a test-sample from KA Olsson and it worked really great. It’s quite expensive, but we got it a little bit cheaper thanks to KA Olsson.

We used straps to tighten the polycarbonate around the corners. We also applied tape at the edges to stop the glue from seep out.