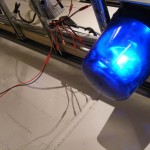

RoBot is a IRC-bot that fades the boundarys between the online-world and the physical. At CRF (Chalmers Robotics Society) we have that problem that people is to busy making robots that we dont notice the IRC-messages that are coming in on our TV-computer. RoBot is looking for certain keywords in the #CRF-channel. So if anyone really want attention in the workshop all they has to do is write tvdatorn (swedish for tv-computer) and blue lights will start flashing and a buzzer will beep.

RoBot (IRC-bot that connects)

RoBot is a IRC-bot that fades the boundary’s between the online-world and the physical. At CRF (Chalmers Robotics Society) we have that problem that people is to busy making robots that we don’t notice the IRC-messages that are coming in on our TV-computer. RoBot is looking for certain keywords in the #CRF-channel. So if anyone really want attention in the workshop all they has to do is write “tvdatorn” (swedish for tv-computer) and blue lights will start flashing and a buzzer will beep.

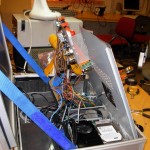

This is how the workshop looks like and when the lights turn on.

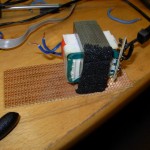

J.K.Abrams has built a device to trigger external devices with 5V from the LPT-port (also known as the Printer-port). He uses a Darlington-amplifier to amplify the signal-outputs from the 8 output-pins on the LPT.

The 5V output can be used to drive a relay that triggers a blue flashing light for example, or a buzzer.

J.K.Abrams LPT-trigger-thingy showing its guts. Eagle-schematics will soon be up…

On CRF’s webpage thare’s a webcam, we have integrated a webbased chat-client for those who don’t use IRC regularly and still want to interact with the people in the workshop.

The source-code and executables for RoBot is available here (VB6 zip), it’s written in Visual Basic 6 and basically acts like an ordinary IRC-client.

I-Are-Bot Ramp

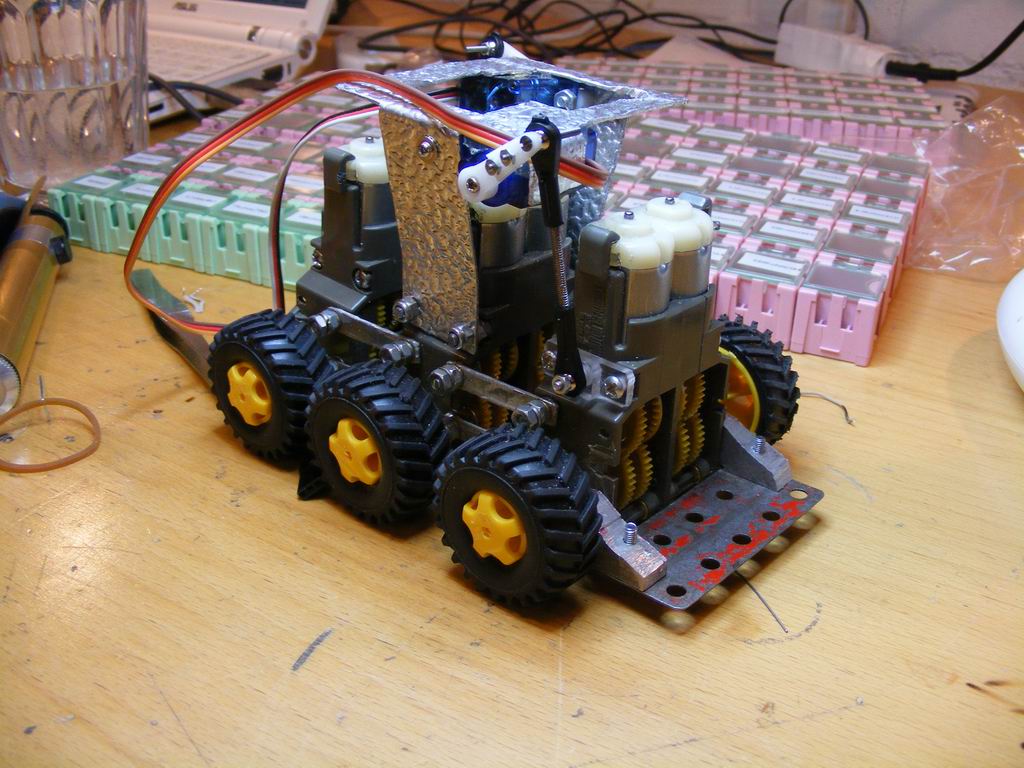

I-Are-Bot needed a ramp so I started working on some prototypes. The idea i got from a forklift, use the weight of the machine to lift. By tilting my servos up an down I can change the angle of the ramp and thereby lift an opponent.

The first two prototypes was discarded as they were too unstable and weak, but the third one turned out pretty well.

The two aluminum profiles attached to the ramp are mounted on the wheel-axis and can be folded. In a angled outright position the ramp touches the side of the gearbox and constrains the ramp to go further down. In a folded state the ramp looks pretty slick, but the ramp prevents the lifting-arm from going up and down. The solution to this was to mount the lifting-arm further up. To do this I’d to build a extra mount, I saw a perfectly good reason to practice my CNC-skills and started CAD:ing.

The ramp can hold much weight, I’ve tried weights around 300g.

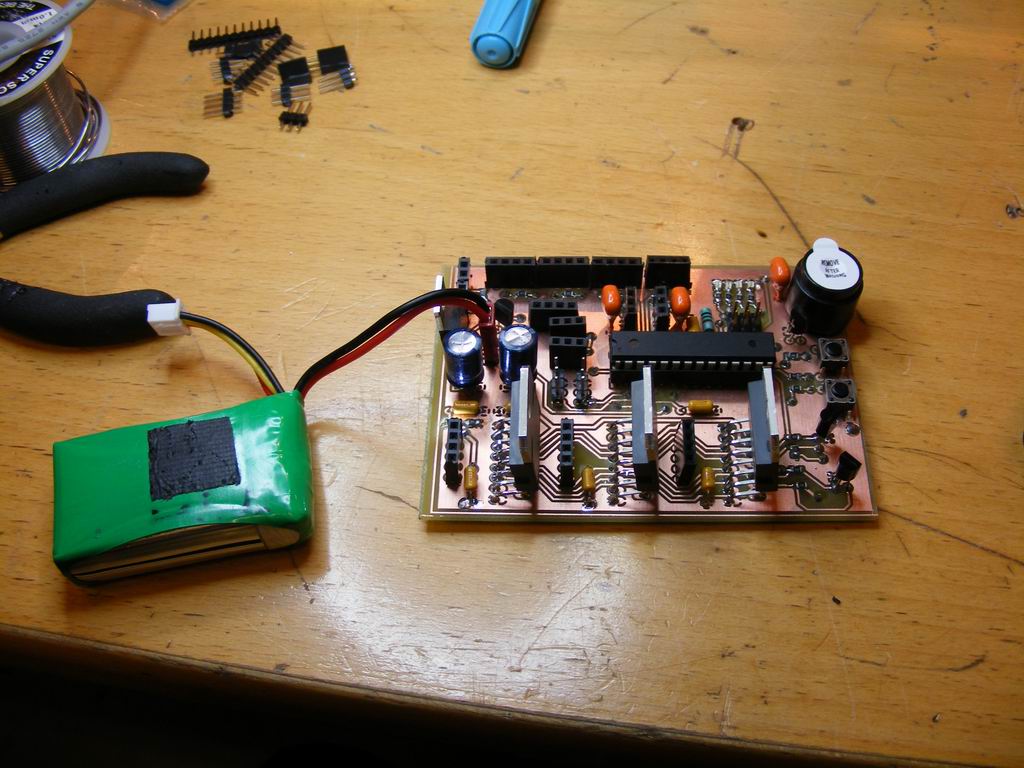

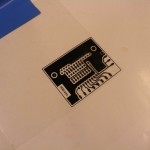

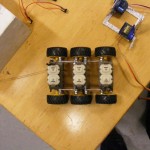

I-Are-Bot’s new PCB

To drive all 6 engines of the same H-bridge is not recommended, it tends to get hot, pretty hot. I was thinking of make a extension card with three H-bridges on it, but then I’d have some weight issues with my bot, it has to weigh less then 500g. The solution was to build a new PCP with htree H-bridges.

Because I never have created a PCB before I was a little bit unsure of how to do it and if I would do any errors. But I’d much help from folks at CRF and it turned out to be a win!

Benjamin at CRF showed me KiCAD which is a great program. It is very user-friendly and you’ll get started quickly. Here’s a great tutorial for KiCAD from CuriousInventor.com.

I drawed the schematics nearly exactly the same as on the Introkit09, but i added two extra H-bridges (L298).

I got a little bit help from Benjamin and Victor to print and make the PCB.

All my resistors and LED’s is surface-mounted so I was a little bit worried that I would have problems while solder. I then watched “Surface Mount Soldering 101″ from CuriousInventor.com and started solder, it turned out to be very easy.

I soldered LED’s with different colors on my PCB, i thought it would be much easier when debuging. I also made up a new ISO for Power-indicators, white LED’s, white! 🙂

Pirat-Bilens tachometer

The Pirate cars PID-regulator get’s goal-value from a tachometer inside the gearbox. A IR-reflex-sensor (ITR8307) is located on the shell off the gearbox and is pointed to one of the gears inside. That gear is painted half black. The tachometer can pick up 6 pulses per revolution of the wheel.

LEGO Fighter

I-Are-Bot

I-Are-Bot is a robot I’m currently working on for Robot SM 2010 (http://www.robotsm.se).

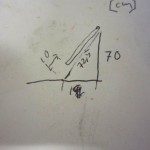

A bot has to be 100×100[mm] to enter the competition, mine was about 130, therefore I had to built an unconventional bot 🙂

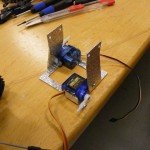

Two mini-tower 9G is lifting each wheel pair.

CAD

To calculate the arm-lengths and servo-positions I had to draw it all in CAD.

Prototype

The prototype turned out pretty well, and after a little fine-tuning did the wheel pairs going up and down without problems.

Video of the CAD and prototype

Pirat-Bilen V.2 @ YouTube

Pirat-Bilen V.2 @ YouTube

“Sven-Erik” in CAD

“Sven-Erik” is a track robot in progress, here’s the CAD-modell of it folding the tracks.

Explodet – Automated fireworks-launcher

Background

Two days after christmas me and my friend, Andreas Svensson, were going to watch Avatar 3D, the tickets was sadly canceled due to SF the bitch. We then started to think of something else to do, Andreas: “..how about that fireworks-launcher we spoke of a few mounths back?..” And so it was decided.

We had a short deadline, roughly about 5 days.

Finished result

BTW. Explodet is short for Explosive Detonator.

Launch-day!

20:00 – At new years’s eve, five days of constant work, we finally made it. It was ready for testing.

21:59 – We arrived at the party, I had not slept for 36 hours

22:06 – I started programming at the party, Andreas went to pick up some equipment

22:25 – Party-cat Sigge was showing interest in Explodet, discrete sniffing and foxy glimts from the eyes was seen.

22:53 – Unfortunately the software wasn’t ready, still had hope I would program it outside

22:55 – We went out to setup all the gear

23:10 – The fireworks launching-ramp was rigged

23:21 – The 230V-generator and 2×500W halogen lights was rigged.

23:40 – Explodet is up and running

23:41 – I found out that it was to cold to program, -15 degrees C. We decided to launch the fireworks remotely (by pushing down spacebar) was good enough.

23:55 – Cable setup

24:00 – Still cable setup

00:01:01 – Success! First firework fuse is sparkling.

00:01:05 – Disaster! The firework won’t lift off, 20 peoples is throwing them selves down the hill.

00:01:30 – It all went well! 🙂

01:15 – The final fireworks went off in a beautiful sparkling rain.

01:16 – Starting to bring the rig down

04:00 – Finally home!

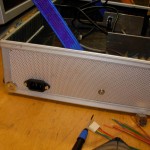

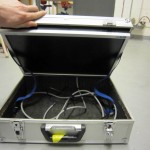

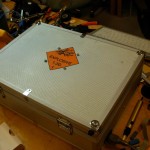

Specs. and parts

- Case: a cheap aluminum-case

- Screen: a leftover from Andreas, Samsung SyncMaster940NW

- Computer: a leftover from Andreas, a minicase with 1GHz Celeron, 760MB SD-Ram, 4xUSB1.1, Firewire, IR-Com, CD-Drive

- Operationsystem is Windows XP Proffessional

- Software: Written in Visual Basic 6.0

- Interfaceboard: Velleman K8061, 33 input/outputs: including analogue / digital and + 1PWM output

- Relay-card: 8×12V Relays

- Battery: PB 12V 7,2Ah

- Ignite-coil: Nikrothal 80 0,7 mm 1 hg

Research at Chalmers Pyrotekniska Förening

Before launch-day I went to visit Chalmers Pyrotekniska Förening. They showed me their fireworks-launching-case, it had 50 manually trigged outputs. They also had a sequencer with 25 automatically trigged outputs.

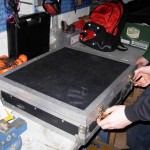

Building process

It was a perfect start of the project: when we first arrived a big christmas-tree made out of coke-cans met our eyes.

Just before the project had started Andreas said: “I’ve 20″ wide screen to no use at home, wouldn’t it be nice to mount it inside?”

I asked him how wide it was. “Roughly 245mm” I went to measure the case “It would fit, the case is 248mm!”

We started out by placing the 20″ screen inside the case. It was a perfect fit!

We marked 4 screws in the screen with paint and then placed the screen inside the case. We then drilled holes were the painted marks.

The next step was to mount something to hold the case-lid up.

We then tested if the screen was working properly, it did. Also notice the mini-computer placed inside the case.

Andreas i starting on the PVC-pipes to the launching-ramp.

I started to build the relay-card. First I mounted a 12V 1A voltage-regulator UA7815.

Flying coke-can in a stream of air.

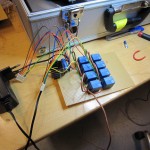

First part-layout-testing. Battery, computer, interfaceboard, relayboard.

The inner case bottom plate is made out of a old computor-chassi-side. I measured it up and started cutting, then i had to bend the plate in order to fit all the switches.

Before painting, I polished the plate down to the steel.

A hole for the air-flow to the computer felt necessary.

To make the construktion sturdy, I manufactured some side-pieces.

In the middle of te 3:rd building-day Peter came around to fix his Guitarhero-controller. We then watched Monsters VS. Aliens an when Peter inserted the audio-cable into his computer he destroyed the christmas-coke-tree. We rebuild it again.

Case-bottom-plate holes for switches, air-filter, mounting of banana-plugs

I had to bypass the ordinary computer-power-switch and mount it on the case-bottom-plate.

Mounting signal-cables and attaching the relay-card

Will the plate fit? Yes indeed! We can even close the case without the switches touching the screen. Thighty!

Andreas is making Nikrothal-coils that will ignite the fuses.

I making a pair of new USB-connectors, the old one burned up! 🙂

The fireworks the bought from Chalmers Pyrotekniska Förening!

In the making of the launching-ramp.

Squeezing the cables nice together.

Erik and Erik came around early at the evening of new years eve to check on the progress.

The final touch on Explodet was the letters and the stickers. Behold!